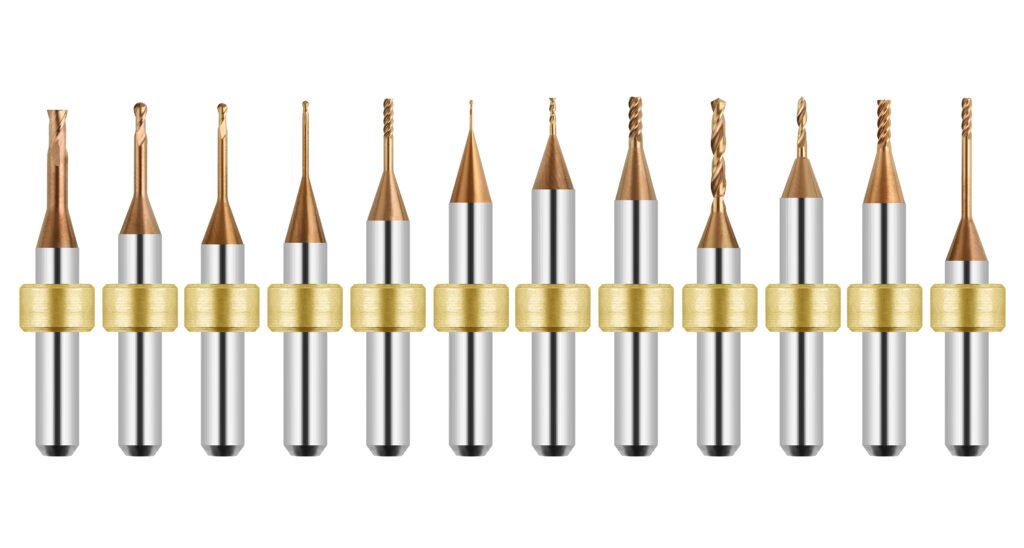

At CapDeg, we specialize in manufacturing high-performance dental CAD/CAM milling burs/ cutters designed for precision machining of various dental materials, including zirconia, glass ceramics, composite resins, wax, PMMA, and metals. We have milling burs compatible with major CAD/CAM systems worldwide, ensuring seamless integration and optimal performance for dental laboratories and milling centers.

Why Choose CapDeg Dental Milling Cutters?

✔ Superior Material Compatibility – Our carbide and diamond-coated cutters are engineered to handle the toughest dental materials with exceptional durability and minimal wear.

✔ High Precision & Smooth Finishing – Advanced geometries ensure accurate milling, sharp edges, and flawless surface finishes for crowns, bridges, abutments, and dentures.

✔ Wide Range of Compatibility – We support all major milling machines, including:

-

Dentsply Sirona (inLab, MC X5, etc.)

-

VHF (R5, K5, etc.)

-

Roland, Zirkonzahn, Amann Girrbach, Ivoclar, Wieland, Imes-icore, and more.

✔ Custom Solutions Available – Need a specialized cutter for unique applications? We offer custom-designed milling tools tailored to your specific requirements.

✔ Cost-Effective Performance – Enjoy longer tool life, reduced breakage, and consistent results, lowering your operational costs.

For Milling Materials Includes:

-

Zirconia Cutters – Optimized for high-strength oxide ceramics.

-

Glass Ceramic & Hybrid Ceramic Cutters – For smooth, chip-free milling.

-

Resin & PMMA Cutters – Ideal for temporary restorations and prototypes.

-

Metal Cutters – Designed for CoCr, titanium, and other alloys.

Custom Orders & OEM Support

We provide OEM services and tailored cutter designs to match your exact milling needs, ensuring compatibility with your equipment and materials.

Upgrade your milling efficiency with CapDeg’s precision-engineered dental milling burs – where innovation meets reliability!

Contact us today for product inquiries, custom solutions, or distributor opportunities.

Email: info@capdeg.com